Page 43 - Taiwan Transportation Equipment Guide (TTG) - 2019-09 Edition - CENS.com

P. 43

Supplier News Supplier News

Chung Ho Cheng Enterprise Co., Ltd.

CHC: Expert of High-Quality Steel, Aluminum and Copper Forging

process allows the firm to guarantee improvements to CHC has an expansive client base around the

their cost management and utilization of raw materials, world: the U.S., Mexico, the U.K., Germany, Belgium,

cutting back on preparation before production and France, Spain, Italy, Turkey, Japan, Thailand, the

eliminate any obstacles beforehand, and most Philippines, Malaysia and Indonesia.

importantly, to achieve on-time production and

By Huang Wei-Shiou delivery. The hundred-year-old automobile industry has

Photo courtesy of CHC entered a new era, Lai said, where it has now evolved

CHC is backed with 30 years of experience into the era of eco-friendly and energy saving hybrid

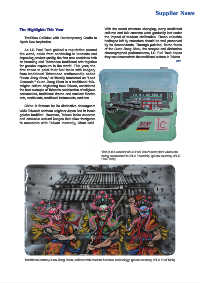

ounded in 1998, Chung Ho Cheng Enterprise steel forging and alloy steel forging products, the in tooling design. Through understanding of the vehicles and electric vehicles. In the face of global

FCo., Ltd. (CHC) is equipped with the experience chairman stated that the firm has laid down plans to properties behind each raw material, the firm is market changes, CHC keeps pace with the trends

to develop professional tooling capabilities. As a hot, cross over into aerospace industrial products. CHC equipped with the unique ability to offer clients the by adopting new transformational strategies. For

warm and combination forging factory, CHC offers keeps a close eye on their production process: from most suitable designs. The firm’s R&D department can example, since aluminum is a lightweight metal,

wide-ranging services like heat treatment and surface the initial stages of raw materials to monitoring factory help clients design new auto parts from scratch, as aluminum forged products are considered the most

the team has a strong background in diverse product

personnel on the production lines, as well as achieving

treatment, all the while rolling out IATF16949-qualified talks with the world’s sixth largest steel mill, Taiwan production and CAE application. Clients can enjoy suitable option for application in the transportation

products. The manufacturer is a major supplier of Steel, to receive a quota of 300 tons of steel each profitable solutions as well, thanks to the firm’s deep- industry. Applying aluminum would reduce fuel loss

and also meet safety standards and demands, making

iron, aluminum and copper forged products for hot month, ensuring the firm’s continual supply of steel rooted experience in the industry. the application useful in the development of the

forged parts like automotive parts, scooter chassis materials and high quality products for clients. Also, automotive industry.

parts, agricultural machinery parts, railway parts, CHC keeps 4,000 tons of raw materials in storage to

defense parts, hardware tools, furniture and fire safety meet varied production schedules. This enables them

equipment. CHC is proficient in developing large-sized to meet their monthly production forging quota of 800

and unique, hybrid-typed parts and prioritizes offering tons of steel and 300 tons of aluminum alloy.

innovative options for their clients through expanding To streamline the production process, the firm also 43

their machinery fleet and optimizing management. allows clients to provide product images, samples or

For example, they have begun to incorporate German 3D models of forging embryo designs or scanning

manufacturing process simulation software SIMUFACT samples to create 3D files, and design molds through

into their systems, allowing them to improve and CAM and CNC. Once the mold is finished, it will be

expand their tooling technology for more precise and moved forward to the production line to manufacture

faster production. samples and sent through a three-dimensional

measuring bed to clarify whether measurements

meet clients’ demands. If the orders are OEM parts,

Chairman Lai Han-chung said his company

is largely built upon tooling development, having the firm would verify the orders through standardized

procedures for operation, inspections, failure mode

manufactured over 3,000 sets since its inception. analysis and effects analysis and monitoring plans

To meet clients’ abundant demands, it took the firm before mass production approval. CHC is a hot, warm and combination forging factory with heat treatment and surface treatment in one roof, and certified

nine times to expand their original 200-ping (661.157 by IATF 16949

square meters) factory to 10,500 ping (34710.744 SIMUFACT helps the firm analyze the process of (photo courtesy of CHC)

square meters). The firm is able to offer small quantity metal usage in tooling production, from extrusion bar

but high variety products with its 11 production chains. metal materials to completed forging products, as well

Through precise production of 150g-53kg of varied as approval of entire production processes of raw

aluminum alloy forging, copper alloy forging, carbon

material properties before forging. The streamlined